KPP-ANTALIS (MALAYSIA) SDN BHD 662405-H

[Southern] Johor

No. 15, Jalan Selatan 3, Taman Perindustrian Ringan Pulai, 81300 Skudai, Johor, Malaysia.

+607-562 4833

+6016-733 3606

+6016-733 3606

+60137783605

Message UsKPP-ANTALIS (MALAYSIA) SDN BHD 662405-H

[Central] Negeri Sembilan, KL & Selangor

Wisma Comcorp 37, Level 3A, Section U1, Temasya Industrial Park, Shah Alam, Malaysia, Jalan Pelukis U1/46, Kawasan Perindustrian Temasya, 40150 Shah Alam, Selangor, Malaysia.

+6016-7133605 (William)

info@imagejunction.com.my

KPP-ANTALIS (MALAYSIA) SDN BHD 662405-H

[Northern] Perak, Penang, Perlis & Kedah

290, Jalan Gurdwara, George Town, 10300 George Town, Pulau Pinang, Malaysia.

KPP-ANTALIS (MALAYSIA) SDN BHD 662405-H

[East Malaysia & Brunei]

Sabah , Sarawak & Brunei

Shoplot No 9, Block D, Ground Floor, Putatan Platinum Plaza, 88200 Putatan, Sabah, Malaysia.

+6016-716 3606

+6016-886 3605

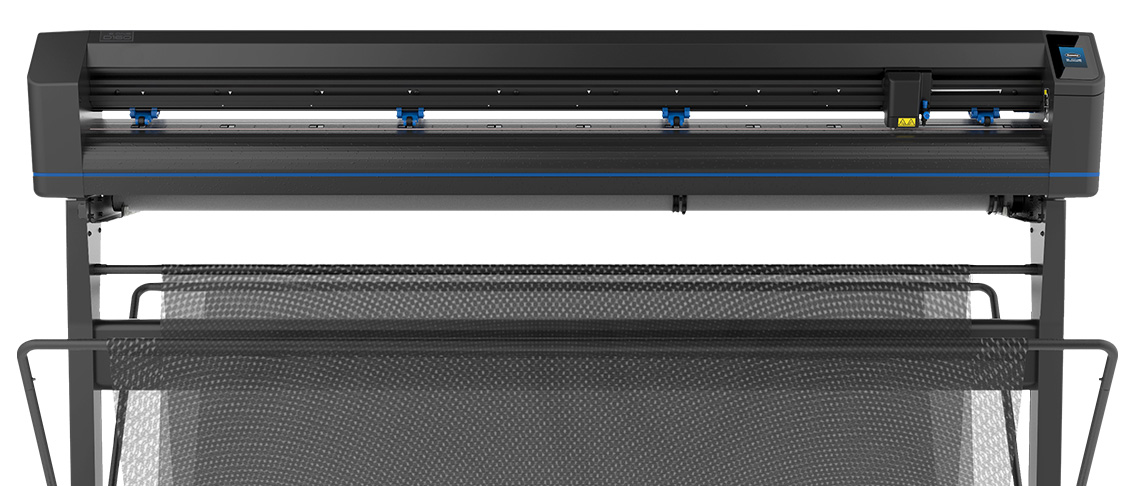

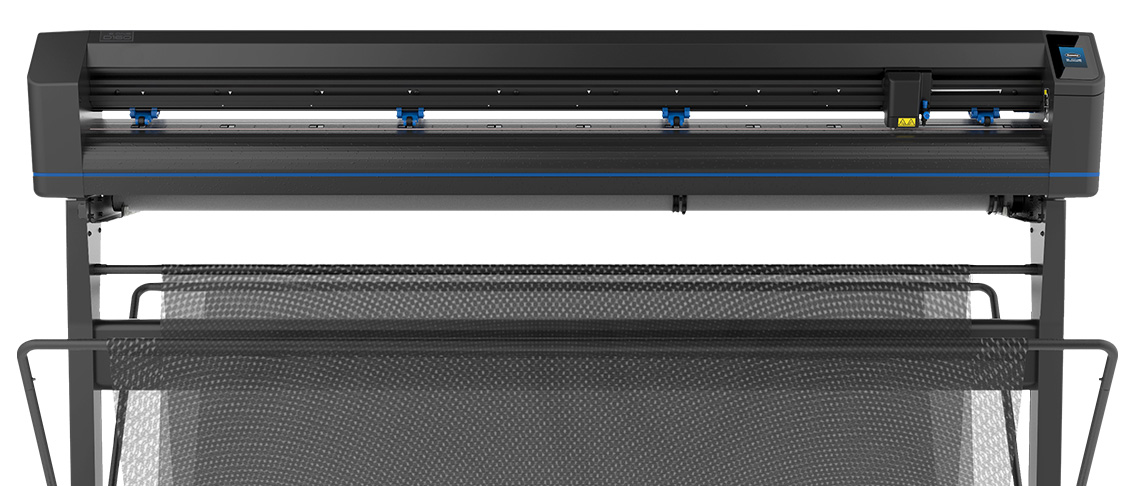

SUMMA S ONE

| Previous | 1 / 4 | Next |

Summa S One SeriesSumma Tray One Sheet Feeder for vinyl cuttersSumma Twin Workflow Vinyl Cutter + Flatbed Cutter Workflow

ADVANCED EASY-TO-USE CUTTER FOR HIGH-VOLUME VINYL CUTTING JOBS

S One™ drag knife cutters include many intelligent features and up-to-date techniques to deliver highest contour cutting accuracy for printed graphics. This combination of advanced features makes the S One roll cutter a flexible and future-proof unit. The perfect companion to grow with your business!

(1).jpg)

TRAY ONE Sheet Feeder For S1 D60

(1).jpg)

TRAY ONE Sheet Feeder For S1 D60

The Tray One sheet feeder enhances automation, facilitates media handling and saves the roll cutter operator a lot of time. Tray One is compatible and retrofittable with S1 D60 models from the Summa S One Series. The combination of our desktop roll cutters with a sheet feeder not only benefits large volume industries but equally focuses on small volume businesses, such as copy shops and retailers. By using Tray One, each copy/sheet will be cut straightforwardly and easily. Sheet after sheet. For hours in a row.

The intuitive menu system and ergonomic touch interface allow for effortless navigation. Tactile and easy to use, the touchscreen displays large amounts of information in an easily accessible format.

OPOS Alignment for smart production

OPOS Alignment for smart production

The Optical Positioning System is an automated contour alignment system. The OPOS X sensor technology senses 4 to 128 marks on a wide range of materials. Enjoy a fully-automated workflow using OPOS barcodes, enabling you to contour cut multiple jobs without intervention.

State-of-the-art drive system

State-of-the-art drive system

The S One servo motor drive system ensures the cutter can still cut at high speeds, even in the most challenging curves. High working speeds are yours to enjoy!

Enhanced ease-of-use

Enhanced ease-of-use

Mechanical adjustable parts are highlighted with a light blue colour, enabling the operator to quickly switch between them. Also, changing tools for a quick setup of the next cutting job is now a child's play.

Ethernet, USB and WiFi connectivity

(1).jpg)

Unmatched Die-Cutting Precision

Ethernet, USB and WiFi connectivity

Multiple computers can control one unit across a network via Ethernet, USB or WiFi. Also, a crossover cable can be used for direct connection - creating an all-new avenue for faster communication and data transmission speeds.

WiFi: Region dependent

(1).jpg)

Unmatched Die-Cutting Precision

Summa's unique FlexCut feature takes cutting technology to the next level. This adjustable feature creates a perforated cut that allows the material to retain the necessary rigidity to transport through the cutter while remaining easy to break apart into individual pieces.

.jpg)

(1).jpg)

GoSign cutting software tailored to your needs

.jpg)

(1).jpg)

GoSign cutting software tailored to your needs

The user-friendly software GoSign is your first choice cutting software, allowing you to manage your preferred workflow with great flexibility. Settings and action sets can be created and tailored according to your specific cutting jobs at any given time.

(1).jpg)

OPOS Xtra to cut intrinsic details

(1).jpg)

OPOS Xtra to cut intrinsic details

The OPOS sensor system reads registration marks blistering fast en compensates bleed automatically. Additionally, the OPOS Xtra functionality is specifically beneficial for the processing of small sticker jobs, detecting curvature changes more accurately than ever.

Legendary tracking for ultimate precision

Legendary tracking for ultimate precision

Summa's exclusive MicroSprocket™ drive drum, coupled with powerful servo motors, delivers jaw-dropping accuracy. Media is conditioned as it advances to guarantee spot-on tracking precision up to 8 m long.

S One FX Series

AN EVER-GROWING RANGE OF APPLICATIONS

S One FX Series

Within this series, there is one model available, the S1 D140FX. The FX only has 400 gr knife pressure and the pinch rollers have fixed positions.

Same specifications as the S1 D140, except: Fixed material widths: 137.2 cm, 122 cm, 100 cm, 91.4 cm, 76,2 cm, 61 cm, 50 cm, 40 cm, 28 cm

400 gr knife pressure

AN EVER-GROWING RANGE OF APPLICATIONS

With the Summa S One Series, you are set to process an infinite range of applications to meet the demands of various markets. Whether it be meticulous detail cutting of laminated vinyl to flock and flex materials, rigid sandblast foils or even a most challenging material type. The S One cutter ensures the processing is done precisely, rapidly and straightforwardly. So, go ahead and boost your creativity now with your do-it-all Summa roll cutter!