IMAGE JUNCTION SDN BHD

782029-W

[Southern] Johor

No. 15, Jalan Selatan 3, Taman Perindustrian Ringan Pulai, 81300 Skudai, Johor, Malaysia.

+6016-733 3606

IMAGE JUNCTION SDN BHD

782029-W

[Central] Negeri Sembilan, KL & Selangor

No.28, Jalan Equine 9C, Taman Equine, 43300 Seri Kembangan, Selangor, Malaysia.

+6016-7133605 (William)

info@imagejunction.com.my

IMAGE JUNCTION SDN BHD

782029-W

[Northern] Perak, Penang,

Perlis & Kedah

07-3-69 D'Piazza Mall, Jalan Mahsuri, 11900 Bayan Baru, Penang, Malaysia.

(Temporary closure. We are moving to a new location in soon.)

IMAGE JUNCTION SDN BHD

782029-W

[East Coast] Pahang,

Terengganu & Kelantan

Lot 2581, Taman Adis Indah Tok Adis, Kuala Ibai, 20400 Kuala Terengganu, Terengganu, Malaysia.

+6016-2013605

+6016-7715605

IMAGE JUNCTION (SABAH) SDN BHD

878274-W

[East Malaysia & Brunei]

Sabah , Sarawak & Brunei

Shoplot No 9, Block D, Ground Floor, Putatan Platinum Plaza, 88200 Putatan, Sabah, Malaysia.

+6016-716 3606

+6016-886 3605

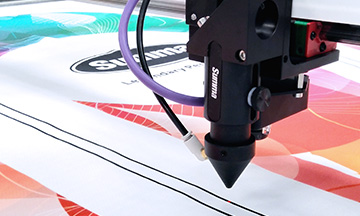

L SERIES LASER CUTTING

| Previous | 4 / 4 | Next |

Summa L Series L1810 2nd GenerationSumma L Series L3214 Fixed Size Laser Cutting

Advanced laser cutting for dye sublimation, printed fabrics and textiles

OPTIMISE YOUR WORKFLOW WITH LASER CUTTING TECHNOLOGY

Whether you are in the industry of fast fashion, sportswear or technical textiles, the L Series serves as a perfect laser cutting system optimised for textile cutting.

THE BENEFITS OF A SUMMA LASER CUTTER

Summa laser cutting machines are developed to help optimizing workflows and to make them worth the investment by delivering:

-

Increased production capacity through automation and high laser acceleration

-

Ease of use through automated options and smart media handling

-

Business continuity through reliable long-life laser tube and high-quality electronics

-

Safe operations with the closed system and the extraction of fumes

- Precise cutting through camera recognition, contactless cutting and sealed edges

Vision Camera System

Contour Cut Vision Trace

The Vision Trace method - tracing the contours of the designs - is advised to use on the L1810 laser cutter and very convenient when cutting sportswear. No cutting file is needed which adds to the automation and ease of use and reduces downtimes considerably. The Vision Camera System is optional on the L1810 laser cutter.

Vision Camera System

Contour Cut Vision Marks

The Vision Marks method - using registration marks - is most beneficial on the L3214 laser cutter, for instance, to process soft signage jobs at fixed-size. The L3214 is standard equipped with the Vision Camera, enabling the use of both methods - Vision trace and Vision marks - depending on your job requirements.

Head Camera System

Registration marks

The head camera system is standard mounted on the L1810 laser cutters (side note: optional on the FB Series). This camera system uses registration marks to process cut-to-size, as well as contour cutting jobs. Increased accuracy and advanced nesting capabilities not only ensure a clean-cut but also reduce material waste substantially.

THE GAME-CHANGERS IN TEXTILE MANUFACTURING

Laser cutters within the L Series are available in three models for which you can choose the power you need. These L Series models are optimised for cutting fabrics. If you need to cut a higher variety of rigid and flexible materials, contact us to discover the FB Series and GraphiXscan. The FB Series offer a bespoke configuration, tailored to your specific cutting needs.

MODEL L1810

SPORTSWEAR - DYE SUBLIMATION

Seamlessly meet requirements for cutting textiles

-

Especially suited to cut textiles

-

Ability to cut all sorts of raw materials

-

Standard equipped with head camera

-

Vision system is optional

-

Suitable for high-production environments

- Fast processing for more throughput in less time

MODEL L3214

SOFT SIGNAGE - LARGE-FORMAT

Meet your customers' deadlines and improve your margin

-

Standard equipped with Vision camera

-

On-the-fly cutting: cutting while scanning in the next part, simultaneously

-

Edge-detect de-reeler ensuring a straight feed of the material

-

The camera scans registration marks or contours using trace

-

Automatic creation of cutting vector

- Suitable for high-production environments

- Cutting typical jobs at 400 m²/hour

SPECIFICATIONS

Our teams are pleased to give you more information and product advice.

.jpg)

| MODEL: | L1810 | L1810 Vision | L3214 |

| LASER POWER | 50 or 100 watts (Air-cooled), 120 or 250 watts (Water-cooled) | 50 or 100 watts (Air-cooled), 120 or 250 watts (Water-cooled) | 250 Watt (Water-cooled) |

| DIMENSIONS |

1030 x 2750 x 2150 mm (HxWxD) All dimensions are displayed without motor de-reeler |

1800 x 2750 x 2150 mm (HxWxD) |

1328 mm x 4382 mm x 3071 mm |

| MAX ROLL WIDTH | 1900 mm | 3400 mm | |

| MAX CUT WIDTH x LENGTH | 1860 mm x Continuous | 3300 mm x continuous | |

| CAMERA RECOGNITION |

|

|

|

| SPEED |

|

|

|

| FEATURES |

|

|

|

| STANDARD SOLUTION INCLUDES | Software ApS-Ethos Cutting Composer, Water chiller (if required), Conveyor system, Visible diode for setup, Compressed air drying bowl and flow regulator,Motion system loop servo motors with hardened ground steel rails,Resolution 0.025 mm,Steel reinforced drive belts,Zero backlash X Belts,Kevlar-reinforced timing belts,Hardened and ground precision motion rails | PC and monitor, Active motorized edge detect de-reeler, Conveyor system, Vision system, Water chiller, Software ApS-Ethos Cutting Composer, Visible diode for setup, Compressed air drying bowl and flow regulator, Vacuum pumps, Centrifugal extraction pump | |